The goal of this program should be started out by changing the pattern of traditional management model to replace passive standby model with active management model. Starting out from the core concept of business operating cost, everything extending from the manpower, material, production costs, and total equipment output derived from the working process must be fully planned out and followed up.

(time availability x function availability x yield rate) is taken as a standard for evaluating maintenance work to reduce overall cost and raise overall efficiency.

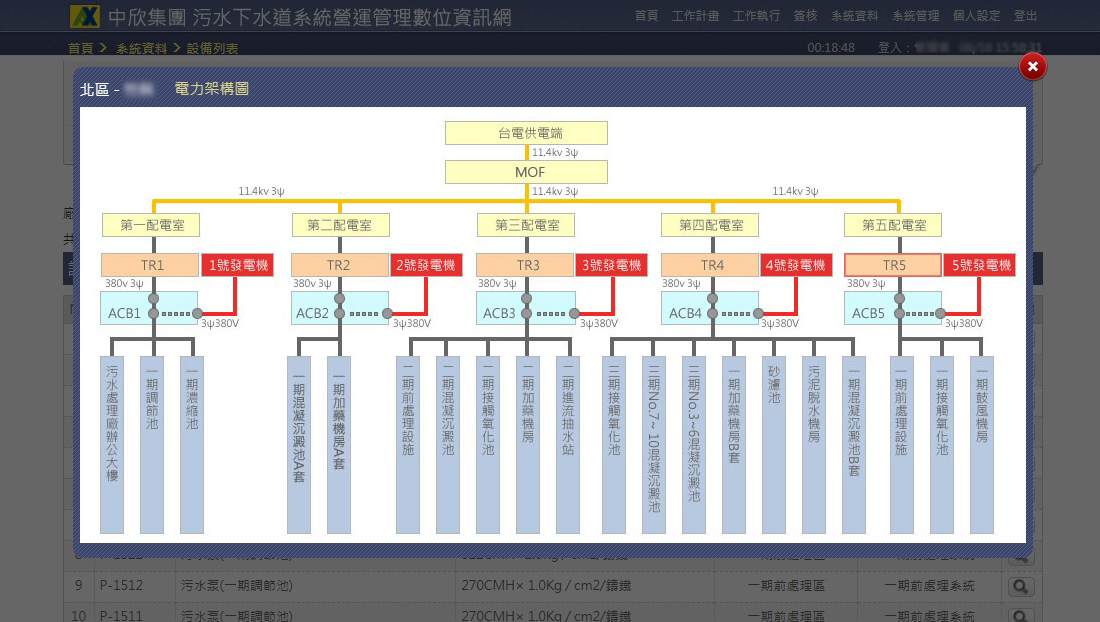

Through the computerization and automation of equipment maintenance management, all kinds of raw data are fully collected and processed to raise maintenance efficiency and reduce human error. All these were done to compute different costs with greater precision, raise equipment reliability, and increase equipment utilization.

Through effective inspection and various verification, normal equipment operation is in check to reduce sudden equipment malfunctioning, increase equipment lifespan, lower maintenance frequency, and cut down relevant cost.

Through the development of a reasonable inventory management plan, diversified management of stock, procurement, storage, and inventory is fully facilitated to track the dynamic inventory status. Based on the guaranteed maintenance cycle and guaranteed maintenance quality, inventory is kept under control to reduce the unwanted situation of overstocking.

Through the effective management of work plan and work order, we assign a certain task to a certain individual instead of assigning a certain individual to a certain task, so that there will be a management, supervision, and data organizing effect for the equipment maintenance.

Through the establishment of an equipment maintenance system, an information system is built to improve the capabilities of information technician and management personnel.